3D printing has revolutionized the way we create and innovate in various fields, from engineering to art. However, even the most experienced 3D printing enthusiasts and professionals encounter a common problem: 3D Printer clogging. When your Printer’s nozzle gets blocked or clogged, it can result in failed prints, wasted filament, and lost time.

3d Printer Clogging? There are several reasons why 3D printers can clog, including poor filament quality, incorrect temperature settings, dirty or damaged nozzles, and moisture in the filament. As a result, it’s crucial to understand the causes of 3D Printer clogging and how to prevent it from happening.

In this article, we’ll provide a detailed overview of 3D printer clogging, the top reasons 3D printer keeps clogging, and the best solutions for preventing and fixing it. Whether you’re a beginner or an experienced 3D printing enthusiast, this article will provide valuable insights to help you achieve successful 3D prints. Read on to learn more!

What is 3D Printer Clogging?

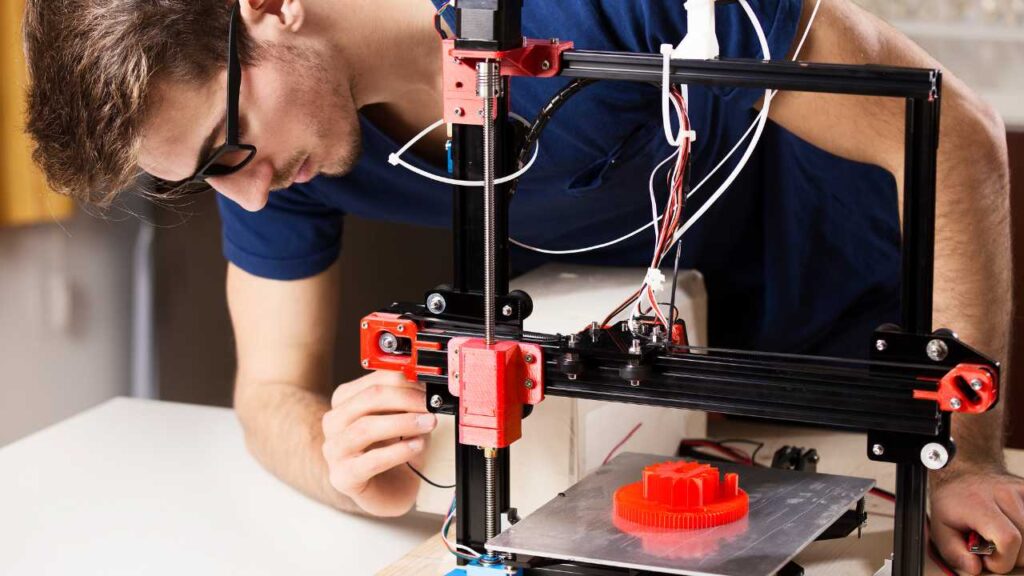

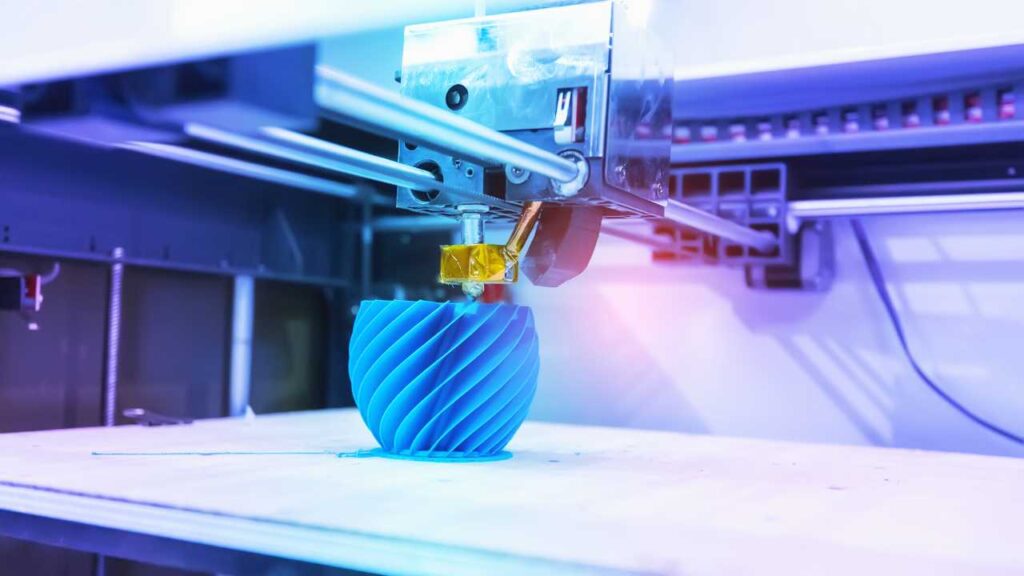

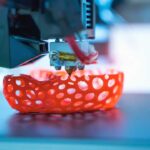

3D printer clogging is a common issue that occurs when the Printer’s nozzle becomes blocked or clogged. The nozzle is part of the Printer that melts the filament and extrudes it onto the print bed. When the nozzle is clogged, it can’t extrude filament properly, resulting in failed prints or no extrusion at all.

Clogging can happen in different parts of the Printer’s extruder, including the nozzle, the heat break, and the cold end. In the nozzle, clogging occurs when melted filament cools and hardens, forming a blockage. In the heat break, clogging happens when the filament melts and drips onto the heat sink instead of passing through the nozzle. In the cold end, clogging can happen when the filament gets tangled or compressed, making it difficult to feed into the Printer.

The effects of 3D printer clogging can vary depending on the severity of the blockage. Sometimes, the Printer may stop extruding altogether, resulting in a failed print. In other cases, the Printer may continue to extrude, but the print quality may be compromised due to under-extrusion or inconsistent flow.

Ultimately, 3D printer clogging can be frustrating and time-consuming, and it’s essential to understand the causes and solutions to prevent it from happening in the first place.

Top Reasons for 3D Printer Clogging

Let’s check out the most common reasons for 3D printer clogging, including poor filament quality, incorrect temperature settings, dirty or damaged nozzle, the print speed that’s too fast or too slow, moisture in the filament, and filament diameter that’s too small or too large. For each reason, the section provides an in-depth explanation of how it can lead to clogging and offers tips on how to prevent it.

Poor filament quality

One of the primary reasons for 3D printer clogging is using low-quality or old filaments. The filament can absorb moisture from the air, which can cause it to swell and become more difficult to extrude. Additionally, the low-quality filament may contain impurities that can clog the Printer’s nozzle. To avoid clogging due to poor filament quality, use high-quality filament from reputable manufacturers and store it in a dry, airtight container.

Incorrect temperature settings

The temperature of the Printer’s nozzle and bed is critical for proper extrusion. If the temperature is too low, the filament may not melt correctly, leading to clogging. On the other hand, if the temperature is too high, the filament may burn and leave a residue that can clog the nozzle. Always ensure the temperature settings are correct for the type of filament you’re using, and regularly calibrate the Printer’s temperature sensors.

Dirty or damaged nozzle

A dirty or damaged nozzle can also cause 3D printer clogging. Dirt, debris, or residual filament can accumulate in the nozzle, obstructing the filament’s flow. Additionally, a damaged nozzle can create irregularities in the filament’s flow, leading to clogs. To prevent clogging due to a dirty or damaged nozzle, regularly clean the nozzle with a soft brush or replace it if it’s damaged.

The print speed that’s too fast or too slow

The print speed is the rate at which the Printer extrudes filament. If the speed is too fast, the filament may not have enough time to melt properly, leading to clogs. Conversely, if the speed is too slow, the filament may cool and harden before it can be extruded, causing clogs. Adjust the print speed to match the complexity and size of the print, and experiment with different speeds to find the optimal settings.

Moisture in the filament

As mentioned earlier, moisture in the filament can cause it to swell and become more challenging to extrude, leading to clogging. To prevent moisture absorption, store the filament in a dry, airtight container with desiccant packets. If the filament is already damp, you can dry it in a filament dryer or oven before use.

Filament diameter that’s too small or too large

The diameter of the filament must match the Printer’s specifications. Using filament that’s too small or too large can cause clogs, as it may not fit correctly through the Printer’s extruder. Always check the diameter of the filament before use and adjust the Printer’s settings accordingly.

Best Solutions for 3D Printer Clogging

Let’s now explore the best solutions for preventing and fixing 3D printer clogging. Following these tips and solutions can prevent and fix 3D printer clogging, ensuring a smooth and successful printing experience.

Using high-quality filament

One of the most effective ways to prevent clogging is by using high-quality filaments. Poor-quality filament often contains impurities or inconsistencies in diameter, which can easily clog the Printer’s nozzle. To avoid this, always purchase filament from a reputable supplier and check for certifications like “food-grade” or “medical-grade” if you need to print specialized items.

Calibrating temperature settings

Another common cause of clogging is incorrect temperature settings. When the temperature is too low, the filament can solidify inside the nozzle, leading to blockages. Conversely, if the temperature is too high, the filament can become too liquid and drip out of the nozzle. To prevent clogging, make sure to calibrate your temperature settings for the specific filament you’re using.

Cleaning or replacing the nozzle

Over time, the nozzle can become dirty or damaged, leading to clogging. Regular cleaning can help prevent the buildup of debris, but sometimes a nozzle replacement is necessary. When replacing the nozzle, make sure to choose the correct size and material for your Printer.

Adjusting print speed

The print speed that’s too fast or too slow can also lead to clogging. Faster speeds can cause the filament to heat up and solidify too quickly, while slower speeds can cause it to melt too much and clog the nozzle. Experiment with different print speeds to find the optimal setting for your Printer.

Storing filament properly to prevent moisture

Moisture is another common cause of clogging, as it can cause the filament to swell and become too large for the nozzle. To prevent this, you can store filament in airtight containers with desiccant packs to absorb any moisture.

Checking filament diameter before use

Finally, it’s important to check the filament diameter before use. Filament that’s too small or too large can easily clog the nozzle. Always measure the diameter of the filament with a caliper before printing to ensure it’s within the recommended range for your Printer.

3d Printer Clogging: Conclusion

In conclusion, 3D printer clogging can be frustrating and time-consuming for 3D printing enthusiasts and professionals alike. It can lead to failed prints, wasted filament, and even damage to the Printer. However, with proper understanding and preventative measures, it can be easily avoided.

We discussed the definition of 3D printer clogging and its impact on the printing process. We also explored the top reasons why 3D printers clog, including poor filament quality, incorrect temperature settings, dirty or damaged nozzles, the print speed that’s too fast or too slow, moisture in the filament, and filament diameter that’s too small or too large.

To prevent and fix 3D printer clogging, we provided useful tips and solutions, such as using high-quality filament, calibrating temperature settings, cleaning or replacing the nozzle, adjusting print speed, storing filament properly to prevent moisture, and checking filament diameter before use.

It’s important to understand and address 3D Printer clogging in order to achieve successful 3D prints. By implementing these solutions, 3D printing enthusiasts and professionals can avoid unnecessary frustration and achieve the desired results.