We always prefer PETG over standard PLA because of its strength and never-failing nature. But because filament companies have now created multiple variations of PLA to minimize the drawbacks and improve its stability. We wondered, is PLA+, PLA Plus, or PLA Pro better than PETG?

The short answer is that PETG is still the king. PLA+ is more potent than standard PLA, but PETG is stronger. Not only stronger, but PETG can also tolerate temperatures that PLA Plus can’t. Not to mention, PETG is quite a bit elastic too.

Also, please don’t get confused with the terms such as PLA+, PLA Plus, PHA, or PLA Pro. They all are the same or, to be precise, similar. Some companies take the standard PLA further, providing it with better characteristics by adding their formulas and mixtures. The resulting filament is known as PLA+, PHA, PLA Plus, or PLA Pro.

So, let’s go a bit deeper into PLA+ (Plus) vs. PETG, and we will also answer some of the most asked questions regarding PLA+ and PETG.

Price: PLA Plus Vs. PETG

Though standard PLA is somewhat cheaper than PETG, that is not the case with PLA+. We even found some variants of PLA Plus being sold for ~$500, which might be somewhat better than cheap PETG, but provides similar value compared to similarly priced PETG.

For instance, we found mid-range PLA+ for ~$25 for a 1kg spool, and surprisingly the print came out great! This ~$25 price bracket is the range where most entry-level satisfactory PETG filaments are available.

In terms of top-of-the-line filaments, both could be priced at over a couple of hundred dollars. Also, note that the quality of the material does influence the price, but we also found some high price materials not to be significantly better than their cheaper alternatives.

Not to mention, any PLA+ or PETG filaments with superimposed materials, like carbon fiber, will be more costly. We mostly use entry-level filaments since they are the most value for money. Also, I’m fond of creating DIY accessories for my garden Shed that we built In A Single Weekend. And sometimes, with entry-level filaments, my projects turn out better than expected.

To be honest, the end results are sometimes way better than we expected.

Characteristics: PLA Plus vs. PETG

One of the significant differences between PLA+ and PETG is how the two filaments are manufactured. PLA Plus is nothing but PLA with added additives. But what exactly does PLA+ contain?

The short answer is that, like PLA, PLA+ is also made out of bio-degradable and natural raw substances such as corn. While the secret formulas of the companies manufacturing PLA+ are not revealed, some speculate one of the added compounds might be TPU.

On the flip side, PETG is, as the name suggests, made out of PET. It is a well-known thermoplastic, and to produce PETG, glycol (G) is mixed with PET (Polyethylene terephthalate) at a molecular level.

Since synthetically made, it has greater strength and endurance. Not to mention its flexibility, which restricts it from becoming fragile when 3D printed. Yes, PETG is entirely recyclable; but it is an oil-based polymer, which means that it is a non-biodegradable filament, unlike PLA Plus.

Properties: PLA Plus vs. PETG

Talking about the material with good physical properties, PETG still stays at the top. Unlike regular PLA, PETG is water, chemical, and fatigue-resistant. However, due to added substances, PLA+ somewhat gets close to the physical properties of PETG. We are stating the obvious, PLA Plus is also more durable than PLA and less stiff.

Below is the table containing the comparison of essential properties of PLA, PLA+, vs. PETG:

| Properties | PLA | PLA+ | PETG |

| Durability | Low | Medium | High |

| Flexibility | High | High | Low |

| Heat/ UV resistance | Low | Low | High |

| Odor | Medium | Low | Zero |

| Strength | Low | Medium | High |

| Toxicity | Low | Low | Low |

| Warping | Low | Low | Medium |

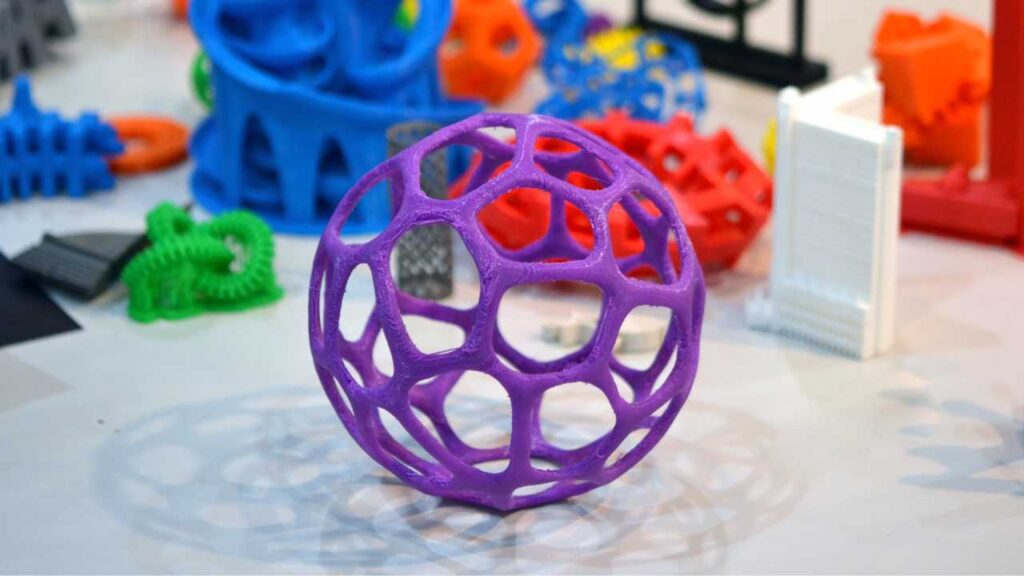

Talking about reinforcements, both PLA+ and PETG can be reinforced with more rigid materials. Adding materials such as Carbon fiber will make them more robust as well as expensive.

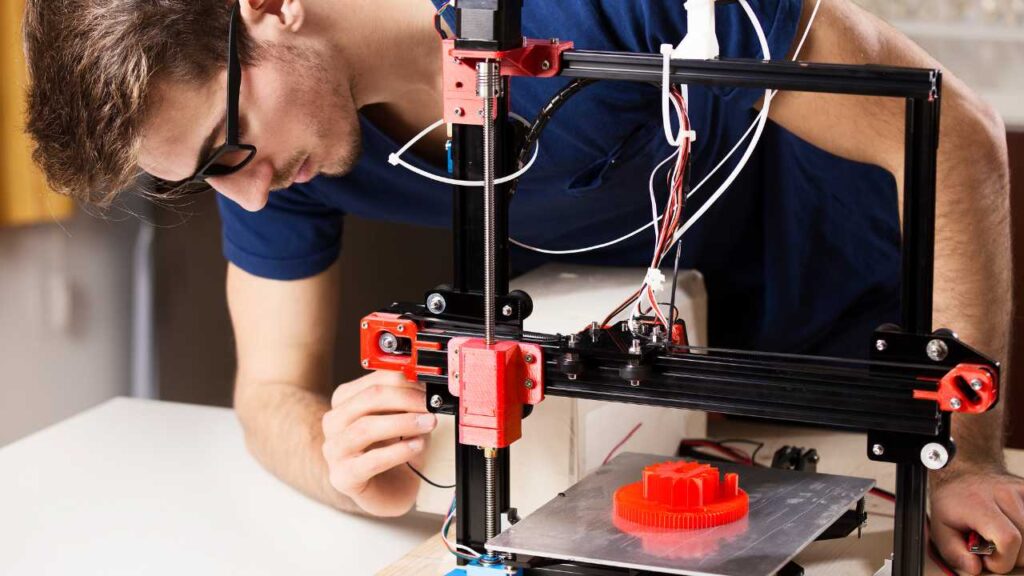

Ease of Printing: PLA+ vs. PETG

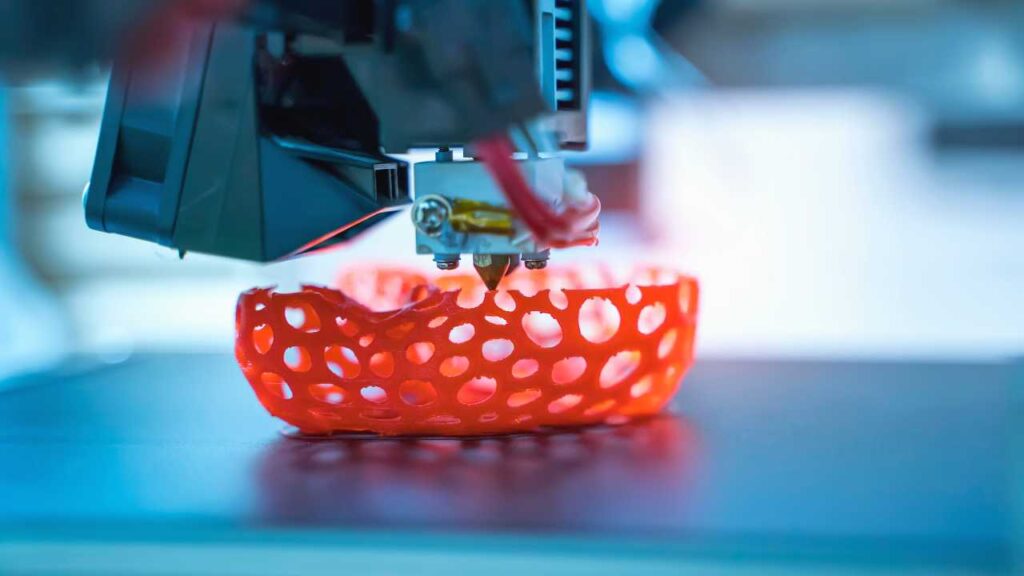

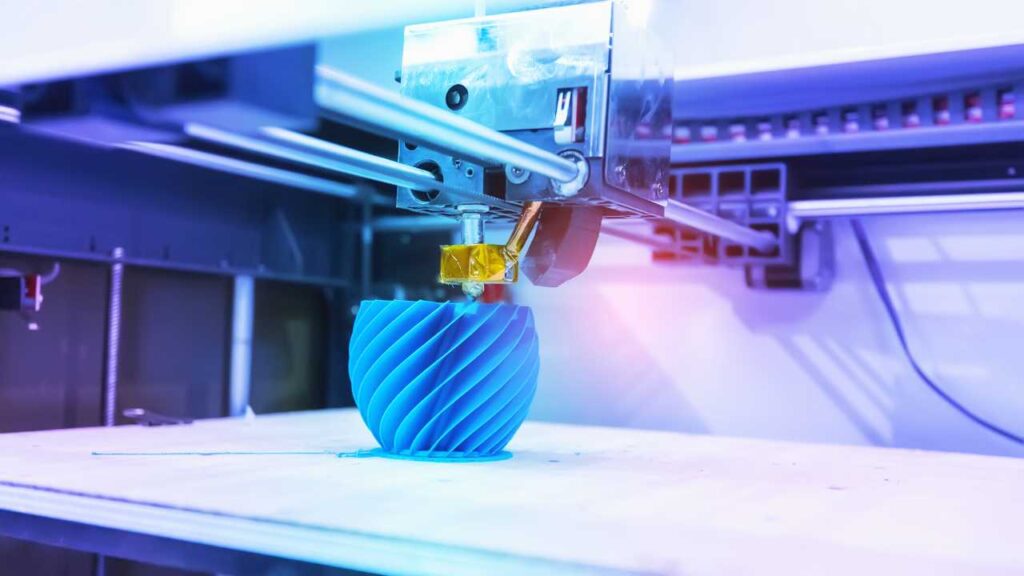

When it comes to 3D printing, the type of filament used plays a crucial role in determining the final product’s quality. PLA+ and PETG are two popular filaments that are often compared for their technical similarities. PLA+ is an enhanced version of PLA, which is made from natural and renewable resources such as cornstarch. On the other hand, PETG is a copolyester that is known for its toughness and durability.

And advancing past the filaments’ main properties, we found technical similarities between PLA+ and PETG. For instance, they both are appreciated for being straightforward to 3D print with. PETG and PLA+ are user-friendly and easy to print in 3D printing. However, some other aspects that determine the ease of printing are:

- Closed Chamber: Some filaments, such as PLA, PLA+, and PETG, don’t need a sealed chamber. This makes it somewhat easier for beginners to print.

- Heat bed: PLA and PLA+ have the edge over PETG, as they don’t need a heated bed. Also, PLA+ is much easier to work with than regular PLA, thanks to its enhanced properties.

- Extrusion temperature: It’s always easier to work with materials that can print in low temperatures. Both PLA and PLA+ have significantly less extrusion temperature than PETG.

- The viscosity of the material: Both PETG and regular PLA are highly viscous materials and sometimes clog printer heads. However, we found that PLA+ is better than PETG and rarely got clogged.

Overall, PLA+ and PETG have their advantages and disadvantages when it comes to 3D printing. While both are considered easy to work with, factors such as heat bed and extrusion temperature can determine their ease of use. By understanding these technical similarities and differences, 3D printing enthusiasts and professionals can choose the filament that suits their needs and requirements.

pla+ vs petg: Post-Processing

Post-processing of 3D printed parts is an essential step in achieving the desired outcome for a project. The post-processing of the parts often involves sanding, polishing, or coloring to improve the aesthetics of the final product. This is particularly important for gifts, where the appearance of the 3D printed part is essential to its value.

When comparing PLA+ vs. PETG or PETG vs. PLA+, the post-processing aspect is an essential consideration. PLA+ is an improved version of PLA and is known for its easy-to-print properties. PLA+ also has a smoother surface finish compared to regular PLA, which can reduce the post-processing time required for polishing and sanding. Additionally, PLA+ is less brittle than regular PLA, making it less prone to breakage during post-processing.

On the other hand, PETG is known for its strength and flexibility, making it a popular choice for parts that require durability. However, PETG has a more textured surface finish than PLA+ and is more challenging to post-process. PETG parts may require more sanding and polishing to achieve a smooth surface finish.

Choice Between PLA plus vs. PETG

When it comes to the choice between PLA plus vs. PETG, PLA+ may be the better option for those who prioritize ease of post-processing. PLA+ parts generally require less post-processing, allowing users to achieve the desired outcome more quickly. However, PETG may be the better choice for parts that require durability and strength, even if they may require more post-processing.

So, post-processing of the printed pars is always a great concern to us. Are we printing the materials for some projects? Will we gift them to someone? It also concerns manufacturers as sometimes the printed parts may need to be removed, colored, or even polished. In regards to pla+ vs. petg, both regular PLA and PLA+ can be painted, while PETG cannot. Also, PETG is transparent and is widely used to manufacture essential goods.

In conclusion, post-processing is an essential step in achieving a successful 3D printed project, regardless of the material used. When comparing PLA+ vs PETG and PETG vs. PLA plus, the choice ultimately depends on the specific requirements of the project, including the desired finish and the necessary strength and durability. However, we conclude that PLA+ does give PETG a good hit. Although they both have their own strengths and weaknesses, one sure thing is that we barely use regular PLA now.

Petg Vs Pla Plus: Conclusion

In conclusion, when choosing between PETG and PLA+, it ultimately depends on the specific needs of the project. PETG is a strong and durable material with excellent impact resistance and is suitable for objects that require high strength and toughness. On the other hand, PLA+ is a user-friendly material that is easy to print with, has enhanced properties compared to regular PLA, and produces high-quality prints.

When it comes to post-processing, PETG requires more effort and skill due to its high viscosity and tendency to warp, while PLA+ is easier to sand and polish. PLA+ also has the advantage of not requiring a heated bed and having a lower extrusion temperature, making it more convenient to print with.

Overall, PLA+ is a great choice for beginners or for those looking for a user-friendly material that produces high-quality prints. PETG is a better choice for projects that require high strength and durability, although it requires more effort and skill for post-processing.

QnA: PLA+ (Plus) and PETG filaments

Is PLA Pro the same as PLA plus?

The short answer is YES; however, they are not the same but similar. The added features vary in different manufacturers, and so does the name. You will find words such as “PLA Plus,” “PLA+,” or “PLA Pro,” depending on the company. However, all are PLA but enhanced.

Is PETG stronger than PLA+?

Is PLA plus or PETG stronger? The answer is that PETG is relatively stronger than PLA+. PLA Plus is much more robust, less brittle, and more durable than PLA, but PLA+ still cant the best PETG.

How strong is PLA plus?

Is PLA plus stronger? The short answer is that it depends on the manufacturer. Typically PLA+ is stronger than regular PLA, but PETG is more robust.

Does PLA plus melt in the sun?

No, PLA+ won’t melt in the sun. However, similar to PLA, it will slowly soften in direct sunlight. Whereas, for better results in the direct sun, we always go for PETG. PETG can also be kept in the car, thanks to its temperature tolerance.